ZD (ZDG, ZDF, ZMD) Self-balancing multistage pomp

Dizze searje pomp is horizontale single suction multistage trochsneed sintrifugale pomp, eigendom 6 nasjonale oktroaien, en mei hege effisjinsje, brede prestaasjes, steady en feiligens operaasje, leech lûd, lange operaasje, maklike ynstallaasje.

It kin leverje it medium mei fêste dieltsjes, boppedat, it kin wurde feroare de pomp materialen, seal type, add cooling systeem dan kin leverje it hyt wetter, oalje corrosive floeistof, en abrasive medium.It materiaal fan pomp: HT200, QT600, JM3, 304, 304L, 316L, Inconel ensafuorthinne.

Wy hawwe trochjûn ISO9001: 2000 kwaliteit systeem sertifisearring, strang kontrolearje de pomp design, produksje en tsjinst, hielendal soargje derfoar dat de pomp kwaliteit.

Model betsjutting

ZD(ZDG,ZDF,ZDY,ZMD)46-30×4

ZD: Self-balancing multi-stage sintrifugale pompen

ZDG: Self-balancing multi-stage boiler feed pompen

ZDF: Self-balancing multi-stage anty-corrosive pompen

ZMD: Self-balancing multi-stage anty-corrosive & erosive pompen

46: Rated Flow is 46 m³/h

30: Rated holle foar 1 etappe is 30m

4: Oantal poadium foar pomp is 4 stadia

-

-

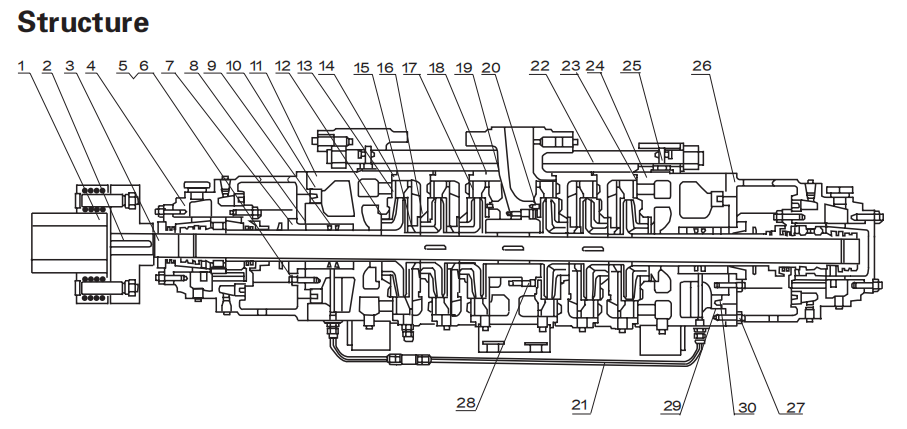

Nee.

Part Namme

Nee.

Part Namme

Nee.

Part Namme

Nee.

Part Namme

1

Coupling Assembly

9

Lantern Ring

17

Discharge Diffuser

25

Air Release Valve

2

Kaai

10

Cooling Keamer Cover

18

Discharge casing

26

Bearing Housing B Assembly

3

Rotating Assembly

11

Suaksje Casing

19

Orifice Sleeve

27

Stoel & Nut

4

Bearing Housing Assembly

12

Wear Ring

20

Dowel Pin

28

Hexagon Socket Head Cap Screw

5

Stud

13

Diffuser

21

Seal Flush Pipe Assembly

29

O-ring

6

Nút

14

Stage Casing

22

Tie Bolt

30

O-ring

7

Packing Gland

15

Inter-poadium Bushing

23

Gasket

8

Packing

16

Wear Ring

24

Scend Suction Casing

Prestaasjegegevens foar ZD, ZDG, ZDF, ZDY, ZMD

Type

Searje

Faasje (r/min)

Streame

(m³/h)

Kop (h/m)

(NPSH)

r/m

Motor Power (kw)

Impeller Dia (mm)

6-25×3

3

2950

6.3

75

2

4

Φ139

6-25×4

4

2950

6.3

100

2

8

Φ139

6-25×5

5

2950

6.3

125

2

8

Φ139

6-25×6

6

2950

6.3

150

2

11

Φ139

6-25×7

7

2950

6.3

175

2

11

Φ139

6-25×8

8

2950

6.3

200

2

15

Φ139

6-25×9

9

2950

6.3

225

2

15

Φ139

6-50×3

3

2950

6.3

150

3

11

Φ198

6-50×4

4

2950

6.3

200

3

18.5

Φ198

6-50×5

5

2950

6.3

250

3

22

Φ198

6-50×6

6

2950

6.3

300

3

30

Φ198

6-50×7

7

2950

6.3

350

3

30

Φ198

6-50×8

8

2950

6.3

400

3

37

Φ198

6-50×9

9

2950

6.3

450

3

37

Φ198

6-80×3

3

2950

6.3

240

3

18.5

Φ235

6-80×4

4

2950

6.3

320

3

22

Φ235

6-80×5

5

2950

6.3

400

3

30

Φ235

6-80×6

6

2950

6.3

480

3

37

Φ235

6-80×7

7

2950

6.3

560

3

45

Φ235

6-80×8

8

2950

6.3

640

3

45

Φ235

6-80×9

9

2950

6.3

720

3

55

Φ235

12-25×3

3

2950

12.5

75

2

7.5

Φ146

12-25×4

4

2950

12.5

100

2

11

Φ146

12-25×5

5

2950

12.5

125

2

11

Φ146

12-25×6

6

2950

12.5

150

2

15

Φ146

12-25×7

7

2950

12.5

175

2

15

Φ146

12-25×8

8

2950

12.5

200

2

18.5

Φ146

12-25×9

9

2950

12.5

225

2

18.5

Φ146

12-50×3

3

2950

12.5

150

2

15

Φ198

12-50×4

4

2950

12.5

200

2

22

Φ198

12-50×5

5

2950

12.5

250

2

30

Φ198

12-50×6

6

2950

12.5

300

2

30

Φ198

Opmerking

Parameter tabel hjirboppe is mar in part fan gehiel.Foar mear, nim dan kontakt mei ús op direkt.

-

1.OEM & oanpassingsfermogen

2.Our eigen gieterij (Precision casting / Sand castings) om snelle levering en kwaliteit te garandearjen

3.MTC en Ynspeksjerapport sil foar elke shipment oanbean wurde

4.Rich operearjende ûnderfining foar projekt oarders